Today’s news of Maker Media’s troubles has made me think. The following thread of ramblings is my (Simon’s) perspective on issues affecting Maker Faires and other events, and the maker movement generally.

I feel that a lot of the issues come from the clash between volunteer led community culture and profiteering & financial realities. The maker community was and is built on the efforts of volunteers, both the behemoth organisers who put on events, or made things happen in the founding of hackspaces, and the smaller efforts of individual makers themselves. But growing success has lead to the promise of profits/rewards in all sorts of ways. I’m not saying this is bad but it distorts the culture in a few ways:

1) Reward hunting vs. doing it for the love of it:

Tailoring activities for greatest rewards. I’m guilty of this: I used to write up my projects to share them with the world, but now I write them up to win instructables contest prizes. These prizes are great motivation; the continuous stream of deadlines makes me finish more projects, more quickly… but only stuff that fits the contest briefs. My limited effort has moved off things that don’t pay back. Only recently have I got frustrated with the lack of art in my activities, and I have made some of my best artistic stuff. I think a similar effect sucks smart proactive people from the maker community to becoming start-ups, youtubers, etc. To survive, these people have to spend a lot of effort on their enterprises, leaving little for volunteer work. People with impressive makes are often paid to attend events, leaving a degree of expectation or demotivation when payment isn’t an option. Also key people in the maker community who put in lots of effort can be demotivated if certain activities give a large income, where other big impact activities are left with zero or even significant personal expense.

2) Secrecy vs. collaboration and open discussion:

When good ideas lead to better rewards, subconscious competitive behaviour ensues. Few people share ideas as freely if the idea has a value (whether monetary or in terms of improving audiences). I recently discussed one of my project ideas to a medium sized YouTube that led to him making an awesome build and a video that got 140k views in under a day. While I have the feeling of being impressed and happy the idea went somewhere, I also have a niggling negative feeling I should have been given some recognition or thanks. That feeling is MUCH stronger given I know this video has helped increase his channel viewership and given him a few hundred pounds in one day. I’m going to try not to let this experience close my openness to discuss things, but on average that is likely to be the broader effect of adding ‘fame and fortune’ value to ideas.

3) Paying customer syndrome:

As events get more expensive, those visiting assume that those exhibiting are paid professionals. This both means they are much less understanding of bodges or failures than they would be otherwise and also there is an assumed separation that they couldn’t do this because they aren’t a professional MakerFaire exhibitor. I’m always shocked when people say they couldn’t do what I do because they have a full time job, so do I folks!

Sellers at maker events treat them as business events and are intolerant of organisational upsets, which only acts to demotivate the largely volunteer organising teams.

4) When the love runs out:

Some volunteers put an exceptional amount of effort into building an organisational monument. Be it EMF, various Maker Faires, founding Hackspaces there are a number of things that are made to happen by committed individuals. These people owe nothing to the world, and have the absolute right to check out at any time. The problem is that keeping the monument going requires someone to step in. The behemoth organisers often hold on after the love is gone rather than seeing their creation fail. It seems the gratitude you get for making something everybody loves is being enslaved by it until it becomes too much, then watching it fall to ruin.

It doesn’t have to be this negative. I think the culture could do much better at highlighting the efforts of the behind the scenes work, showing that those heros that make things happen are normal people with day jobs, and also generating an expectation of people volunteering if they are active in the community rather than feeding the false dream that you’ll make you fame and fortune, be it on YouTube or as a start up. That way, the limited effort people have to spare could be encouraged to focus on something useful.

I think EMF is a great example of this. Despite paying a serious ticket price, there is a continuous reminder that there is an expectation that everyone volunteers. Also the recent open discussion about Jonty and Russ looking to hand over the reins not just in the back rooms chats with ‘insiders’ but publicly at the closing ceremony is a great thing. They remind people that this is a community event with outstanding individuals running it, that it shouldn’t be taken for granted, and that people should step in and help.

5) The startup maker fallacy

One of the critical issues I perceive in the culture is that several parts of the community are trying to rebrand startups as the maker movement. Apparently, THE successful outcome for a maker is to form a start up, and all makers want to do this. Utter nonsense

Don’t get me wrong, I don’t mind business being made in the maker movement, companies like Sparkfun and Adafruit add some of the best resources and impetus to the community, and their products are a great help in achieving great projects accessible to inexperienced makers. But there is a current theme to much of the material piped into the maker community that the successful outcome for a maker is to start a business from it. Whether it is questions in makers hour asking about how your business operates, Hackaday prizes and other competitions offering a prize of funding the launch of your startup based on your idea, or the incessant yap of cynical start-ups that say they are the new best thing for makers.

Recently many have commented that an enterprise that becomes successful has by definition moved out of the ‘maker’ category. I disagree, but I think any ‘for makers’ business should spend a significant fraction of its time and effort helping the community with support documentation and tutorials (not just a single set of instructions) of how to use and preferably misuse the kit; Adafruit being the shining example. Digikey sell things makers can use, where Adafruit sell products for makers.

As for whether makers all aspire to turn their makes into products… I certainly don’t. believe the attraction of making is a means of creative expression, within the constraint of time tools, budget and expertise. If it is too easy, too unoriginal, or too unconstrained, the rewarding feeling is not there. For example, building a kit is fun if you don’t think you can make that sort of thing, but lacks the satisfaction of something that has your creative input and originality. And if you do something as a business, you need to be efficient; that often means gaining suitable expertise and tools, and then making lots of the same thing. That doesn’t scratch the maker itch very well. I’m often told I could go into business selling some of the better things I’ve made. I probably could, but I know I wouldn’t enjoy it because it would suck the fun out of it; I have to concentrate to not lose interest before finishing a one off for myself… Inventing things and then designing them to a saleable quality sounds like my day job, and I already have one of those, and I operate better in a company than I would going it alone.

6) Together we stand, divided we fall:

I guess the other challenge is that makers are naturally creative and would much rather envisage their own new event than help with one that isn’t quite how they’d do it. We should implore people to be more collaborative and less divisional, and in turn be more inclusive of others’ ideas if they are backed up with hard graft to help make things happen.

7) Maker events should feature real “grass roots” makers:

…and preferably a wide variety of them. Maker events really need to ensure they select their content carefully. I believe this is behind the falling attendance at the Bay Area Maker Faire over the last few years.

I went in 2016, and while I did enjoy it, it was difficult to find makers or their exhibits between the big business pet projects and the startups and kickstarter start-up wannabes. Over 50% of what was there was 3rd rate start ups and would be kickstarters trying to catch the maker startup bandwagon.

There was a particularly irritating abundance of people with microcontroller boards that were *apparently* much better than an Arduino that would never have the documentation or libraries of Arduino trying to sell them to unsuspecting would-be makers who would be forever put off by them.

This is a common trait that gnaws at the heart of the maker industry: This popular open source project could be improved, I could join the team and improve it or I could set up a business and undermine it with a better on paper but unsupported.Or worse I could steal the open source design and make it cheaper, undermining it with no pretence of benefit.

There were so many people trying to sell kits or get backers. Some of them were even mildly interesting, but I didn’t cross the Atlantic to come to a big trade show, and parents definitely wouldn’t appreciate taking their kids to inspire a make-not-buy culture only to be walking through halls and halls of gizmos being sold.

Maybe my UK Maker Faire experiences set my expectations too high, but I was expecting more eccentric creative exhibits.

Much of what was interesting there was out of reach of real life people, either professional paid shows (such as the giant version of the board game mousetrap) or the interesting projects of big industry (e.g. DoE personal aircon robots to follow you around and keep you cool or Google’s spin out motion stabilised spoon for Parkinson’s sufferers). Average Joe builds were few and far between. There were a good few eccentric vehicles, like giant penny-farthing like tricycles, the giraffe that Adam Savage appeared on was awesome and just about achievable (suspending some disbelief about cost and storage challenges!), there were cup cake cars that zoomed around, and there were a fair few art installations such as welded sculptures and fireball generators. It’s just for the big Maker Faire, oodles of times larger than the old Newcastle Maker Faire, there were comparatively few impressive builds that were in any way accessible in terms of realistic budgets for makers. I came away feeling it was most notably an event of impressive budgets rather than impressive ideas… It is very easy to make an impressive build if your budget is thousands.

As a result, the degree to which the event inspires people to make interesting things and participate in the maker community is significantly reduced, instead people who go are encouraged either to buy stuff that they won’t use, or try to think of their own start up. So, despite being in the target audience and previously keen, I decided I’d not go back, and I suspect that even without the cost of flights, the non-trivial ticket cost would mean that a fair few locals might be of the same opinion.

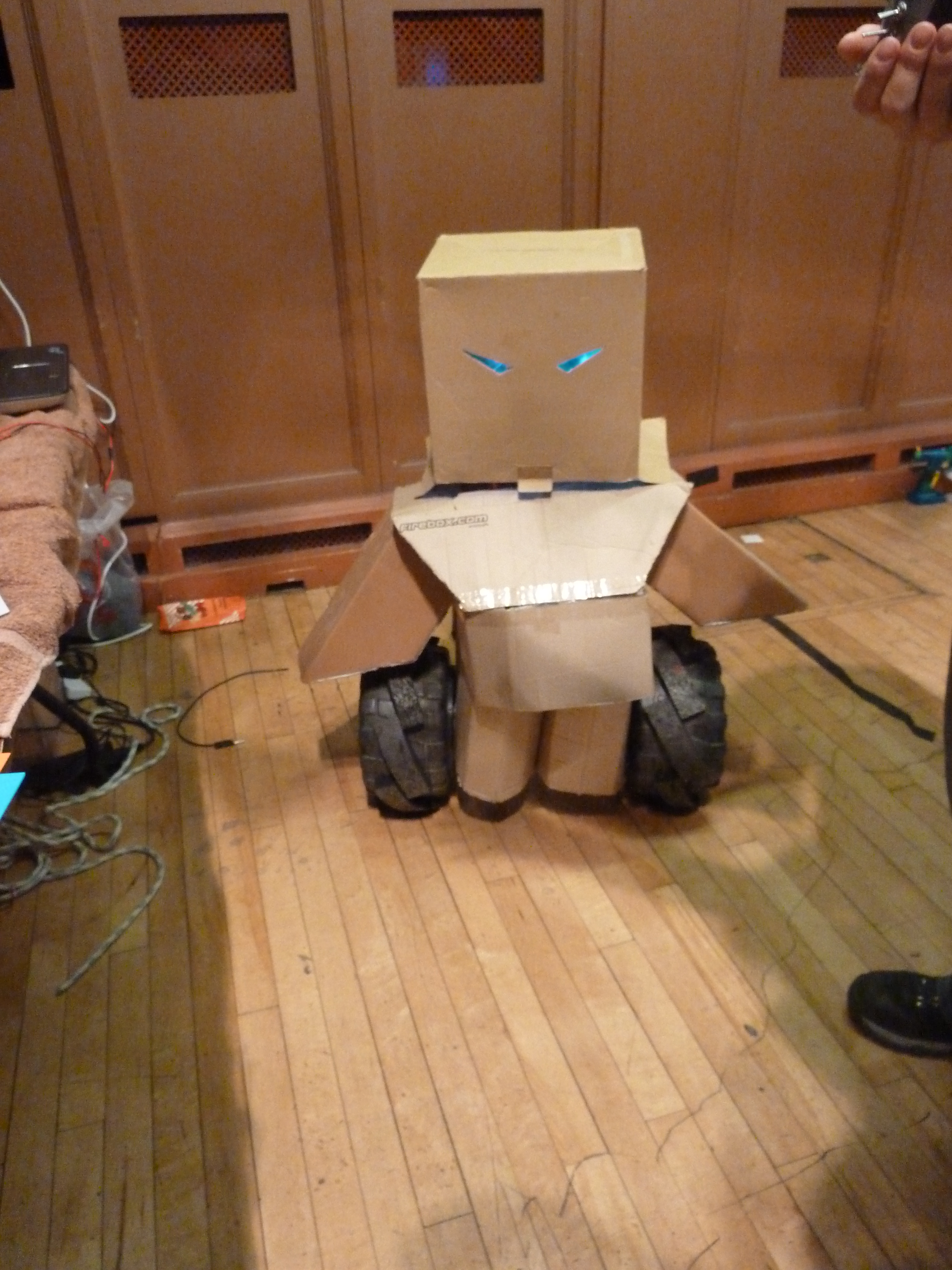

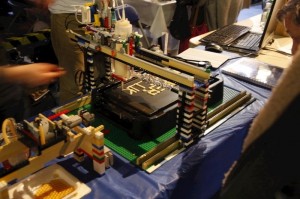

The best Maker Faires I have been to have been UK faires such as Newcastle, Derby and Brighton. The variety of exhibits I can remember off-hand is incredible, from inflatable tentacles, through strange tweeting taxidermy, medieval yarn spinning techniques, musical floppy disk drives, very geeky mini-golf coarses, giant cardboard spiders, revolving caravans…. the list goes on. 80% of stalls are ‘normal’ makers. At most UK events the number of businesses exhibiting has been lower, and those that there have been a good fit; either exhibiting projects rather than just products, or craft maker-sellers (e.g. knitted spectroscopy scarves). I think the only disappointing Maker Faire I’ve been to in the UK was one in Elephant and Castle that felt like it could have been a Kickstarter tradeshow, but perhaps I was in a funny mood having seen a girl cycle into a moving car that morning.

Interesting shows, and things to buy can maker up some of a maker event, but to be a true maker event there should be things that you as a punter could make if only you’d had the idea. Accessible builds inspire would-be-makers to try building their own ideas.

A lot of makers I know came away quite negative about Makers Central. Some of the issue was a strong domination by craft, especially woodwork. Is that a problem? Not as such, wood working is as valid a maker pastime as 3D printing, laser cutting, soldering, programming, or grinding and welding, but an event that uses the tag line “*THE* event for the maker community” should probably make more of an effort to include more of the maker community. But I don’t think woodwork focus is the only issue, I think the biggest issue is the balance of business and maker exhibits. Unlike Maker Faires, Makers Central doesn’t have a call to makers, instead advertising paid pitches. EXPENSIVE paid pitches. There may actually be interest in giving free plots to interesting maker exhibits, but there’s no communication of this that has reached me if so. As a result, as a punter the place feels like a trade show. It’s interesting to look around all the tools on sale, and it was great to get hands on with a few tools that I’d be unlikely to try in other circumstances, but it wasn’t really a very ‘maker’ event. Aside from a few exceptions (Hacky Racers for a start) there wasn’t much creative making beyond using a tool designed for a job to do that job. The only big makes were by superstar YouTubers, making them about as accessible to the average punter as buying one of the CNC routers on sale. The message the event was giving was something like “Here is a great maker who makes awesome flame throwing vehicles, and you can make table if you buy a lathe and a planer-thicknesser”.

To be more than ‘meet Colin Furze, drool over a £3000 CNC router, then maybe buy a chisel’, Makers Central needs to embrace more of the maker community, and actually invite some normal makers.

So what now for UK events? Maker Faires (even aside from whether the name is there to licence) seem to be in short supply. Brighton stopped a few years ago when no-one took over organising it after the organisers stepped down. Newcastle is gone now too. Glasgow has postponed to 2020, and I understand Derby is awaiting reopening. I’m not aware of a single 2019 Maker Faire event. MakeFest in Liverpool is the only remaining maker event I’m aware of, and I only found out about that after call for makers had closed ![]()

Where am I going with this? Who knows? But I think I’ve talked myself into a few opinions:

- I think Maker Media becoming a not for profit would be a good outcome (rather than acquisition by another business that wants to add another business spin using bought brand heritage).

- I think the maker community should decouple itself from the push into forming startups, and should try to work out what maker really means. Fiddling with electronics to make a product isn’t being a maker, fiddling with electronics to express your creativity is.

- I think there should be more public discussion (as well as applause for) the way people who make our community and events make things happen. Present it as accessible, as these people are human, not gods. There is a tendency to try to make events and institutions swan like, presenting an unmoving facade of ‘professionalism’ and hiding all the activity that keeps things going under the waterline. This should be reversed!

- I think there should be more maker events in the UK, and these should focus on grass roots making.

- Finally, I think trying to be more cohesive and united as a community would help. Local communities can be strong, but we should build a UK united maker community. There is too much moaning and not enough doing (me included). Despite the creative drive to do our own thing, we should try to support and improve a united whole rather than adding more fragmentation. Ideally a centralised calendar of what events are happening when would be nice too!